Industry News

NEWS

What Prevents Automatic Transmissions from Overheating and Failing Prematurely?

Automatic transmissions rely on fluid circulation to maintain proper temperature and lubrication. When this system fails, the transmission can suffer significant damage, leading to costly repairs. Understanding the components that keep transmission fluid at safe operating temperatures helps vehicle owners make informed maintenance decisions.

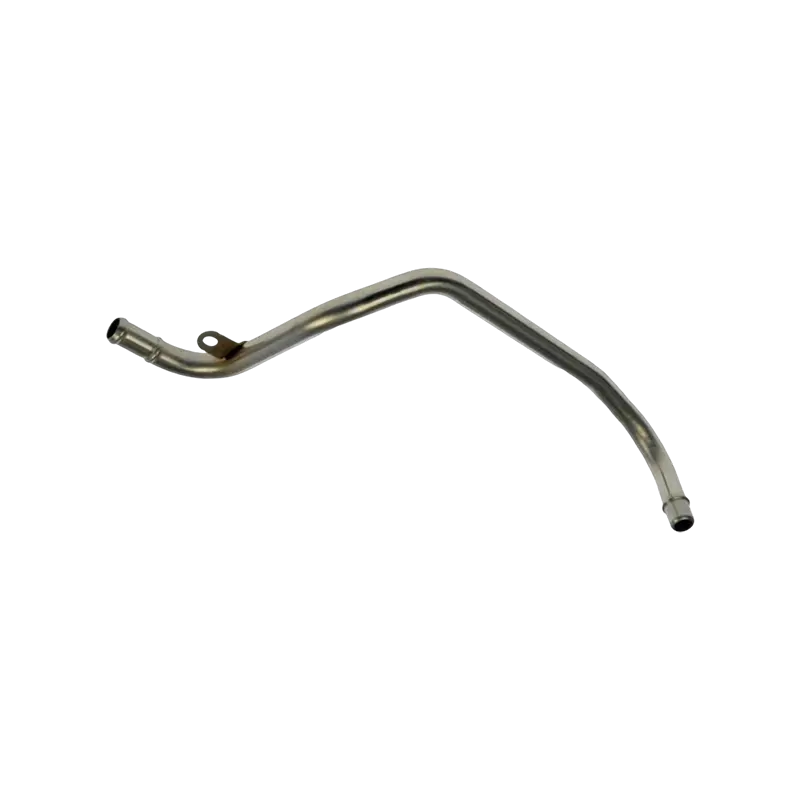

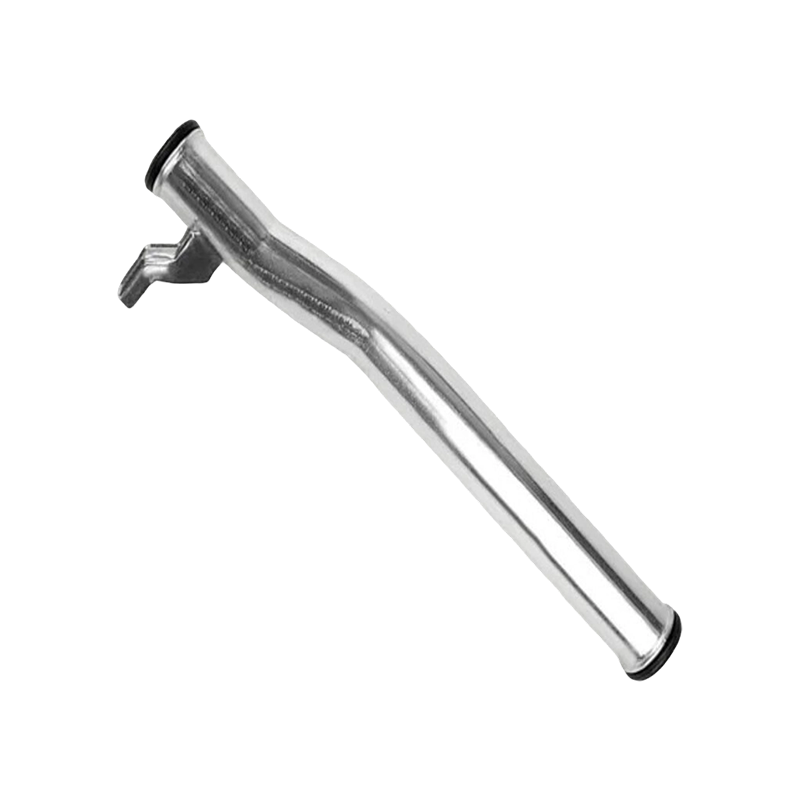

One component that often gets overlooked in routine maintenance is the transmission cooler line. This assembly plays a fundamental role in connecting the transmission to the radiator cooler, ensuring fluid circulates efficiently to dissipate heat.

Understanding Transmission Temperature Regulation

Transmission fluid serves multiple purposes: it lubricates moving parts, transfers power, and crucially, removes heat generated during operation. When transmission fluid becomes too hot, it loses its ability to lubricate effectively, which can cause accelerated wear on internal components.

The cooler line acts as the conduit for this heat exchange process. It carries hot fluid from the transmission to the radiator cooler, where heat is dissipated before the fluid returns to the transmission at a lower temperature. This continuous cycle is essential for maintaining consistent operating temperatures, especially during heavy use such as towing or driving in stop-and-go traffic.

Signs Your Cooler Line May Need Replacement

Like all components in a vehicle, cooler lines can degrade over time. Being aware of potential warning signs can help prevent more serious transmission issues. Some indicators that your cooler line assembly may need attention include:

- Visible fluid leaks underneath the vehicle

- Burnt smell coming from the transmission fluid

- Difficulty shifting gears smoothly

- Transmission warning light illumination

- Unusual transmission operating temperatures

Addressing these symptoms promptly can prevent more extensive damage to the transmission system.

Why OEM-Style Engineering Matters

When selecting replacement components for your vehicle, the quality of engineering can significantly impact performance and longevity. Generic replacement parts may not meet the exact specifications required for your specific vehicle model, potentially leading to fitment issues or reduced durability.

Precision-engineered components designed to replicate original equipment specifications offer several advantages:

| Feature | OEM-Style Components | Generic Alternatives |

|---|---|---|

| Fitment | Direct fit, no modifications needed | May require adjustments or custom fitting |

| Material Quality | Matches original specifications | Varying quality levels |

| Pressure Rating | Designed for system-specific pressures | May not match OEM pressure requirements |

| Temperature Resistance | Engineered for high-temperature operation | May have lower heat tolerance |

| Warranty Support | Often backed by manufacturer warranty | Limited or no warranty coverage |

As shown in the table above, OEM-style components provide consistent performance and reliability that helps maintain the integrity of your vehicle's transmission system.

Installation and Maintenance Considerations

Proper installation of a transmission cooler line is crucial for leak-free operation. When replacing this component, it's important to:

- Ensure the transmission fluid is at the correct level before and after installation

- Follow manufacturer torque specifications for all connections

- Check for proper alignment and routing to prevent kinks or rubbing

- Inspect related components for wear or damage

- Test the system for leaks after installation

Regular inspection of the cooling system as part of routine maintenance can help identify potential issues before they become major problems. This includes checking for signs of wear on hoses, connections, and mounting points.

Benefits of Maintaining a Healthy Cooling System

Investing in quality replacement components and maintaining the transmission cooling system offers several long-term benefits:

| Benefit | Description |

|---|---|

| Extended Transmission Life | Proper temperature control reduces wear on internal components |

| Improved Performance | Consistent fluid temperature supports smooth gear shifting |

| Reduced Repair Costs | Preventing overheating avoids expensive transmission repairs |

| Better Fuel Efficiency | Properly functioning transmission operates more efficiently |

| Enhanced Reliability | Quality components reduce the likelihood of unexpected breakdowns |

Environmental and Operating Conditions

Different driving conditions place varying demands on the transmission cooling system. Understanding these conditions helps vehicle owners appreciate the importance of maintaining a healthy cooler line assembly:

Heavy Load Situations: Towing trailers or carrying heavy loads increases transmission temperature. A properly functioning cooling system becomes essential to prevent overheating during these demanding conditions.

Extreme Temperatures: Both hot and cold climates present challenges. High ambient temperatures make cooling more difficult, while cold weather can affect fluid viscosity. A reliable cooler line assembly helps maintain consistent performance across temperature ranges.

Stop-and-Go Traffic: Urban driving conditions with frequent stops reduce airflow across the transmission cooler, making the cooler line's role in fluid circulation even more critical for temperature management.

Choosing the Right Replacement Component

When selecting a replacement cooler line assembly, vehicle owners should consider several factors to ensure they receive a component that meets their needs:

- Compatibility with specific vehicle make and model

- Material quality and construction standards

- Manufacturer reputation and customer support

- Availability of warranty coverage

- Past performance and reliability ratings

Choosing a component that replicates OEM engineering helps ensure the replacement will perform as intended, providing peace of mind and reliable operation.

Conclusion

The transmission cooling system plays a critical role in maintaining transmission health and longevity. While often overlooked, components like the transmission cooler line are essential for ensuring proper fluid circulation and temperature regulation.

By understanding the signs of wear, choosing quality replacement components, and maintaining the cooling system as part of regular vehicle maintenance, owners can help extend the life of their transmission and avoid costly repairs. Investing in precision-engineered components that replicate original specifications provides a reliable solution for maintaining vehicle performance and reliability.

Content

- 1 Understanding Transmission Temperature Regulation

- 2 Signs Your Cooler Line May Need Replacement

- 3 Why OEM-Style Engineering Matters

- 4 Installation and Maintenance Considerations

- 5 Benefits of Maintaining a Healthy Cooling System

- 6 Environmental and Operating Conditions

- 7 Choosing the Right Replacement Component

- 8 Conclusion

Our Main Products

Contact Us

Contact Us

+86-138 0586 3066

+86-574 8840 6311

Send An E-mail

Send An E-mail

Mobile

Mobile

Copyright ?NINGBO JIATIAN AUTOMOBILE PIPE CO.,LTD. All Rights Reserved.

English

English Espa?ol

Espa?ol