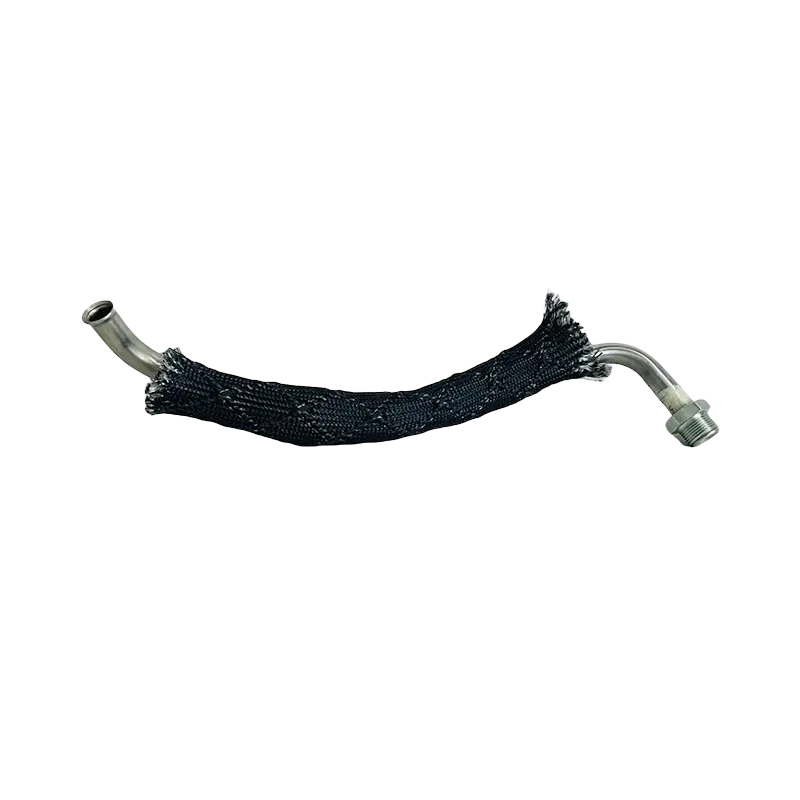

Complete Analysis of OE E9SZ9D477B Stainless Steel Replacement

When your vehicle experiences performance degradation, reduced fuel efficiency, or emission warning lights, the culprit might be an often-overlooked component: the EGR (Exhaust Gas Recirculation) tube. Today, we delve deep into the EGR tube assembly with OE number E9SZ9D477B, exploring how this high-performance stainless steel replacement part from NINGBO JIATIAN AUTOMOBILE PIPE CO., LTD. addresses common EGR system issues, providing you with a comprehensive purchasing and maintenance guide.

Key Takeaway: The EGR tube is a critical component connecting the exhaust manifold to the intake manifold, responsible for redirecting a portion of exhaust gases back to the combustion chamber to reduce nitrogen oxide emissions. Over time, carbon buildup and high-temperature corrosion can cause failure, and the OE E9SZ9D477B replacement offers a durable stainless steel solution.

Why is the EGR Tube So Crucial for Your Vehicle?

The Exhaust Gas Recirculation system is essential technology in modern internal combustion engines for reducing harmful emissions. By reintroducing a portion of exhaust gases into the combustion chamber, it lowers combustion temperatures, effectively reducing nitrogen oxide (NOx) formation. The EGR tube serves as the "artery" of this system, with its integrity directly impacting overall system performance.

However, EGR tubes operate in extreme conditions: continuous exposure to high-temperature exhaust gases (reaching 600°C+), enduring severe thermal cycling stress, and contact with corrosive combustion byproducts. Factory EGR tubes made from ordinary steel often develop cracks after several years due to corrosion, carbon clogging, or thermal fatigue, leading to exhaust leaks and subsequent problems.

Common Symptoms of EGR Tube Failure

Recognizing early signs of EGR tube failure can prevent more serious engine issues:

OE E9SZ9D477B Stainless Steel EGR Tube: Technical Details and Advantages

Addressing common failure modes of factory EGR tubes, the OE E9SZ9D477B EGR Tube Assembly developed by NINGBO JIATIAN AUTOMOBILE PIPE CO., LTD. provides a comprehensive engineering improvement solution.

Premium Materials: Superior Performance of T304 Stainless Steel

Unlike many factory parts using ordinary steel or low-grade stainless steel, this replacement is manufactured from T304 stainless steel, a premium material commonly used in aerospace and high-end automotive applications. T304 stainless steel contains 18-20% chromium and 8-10.5% nickel, offering multiple advantages:

High-Temperature Oxidation Resistance: Chromium forms a dense chromium oxide protective layer on the surface, preventing further oxidation even under continuous high temperatures. This means the pipe interior won't gradually "rust away" like ordinary steel in environments with fluctuating exhaust temperatures.

Thermal Fatigue Resistance: The EGR system experiences severe thermal cycling—from ambient temperature at cold start to 600°C+ under full load. T304 stainless steel's excellent thermal expansion coefficient and strength retention capability allow it to withstand thousands of such cycles without developing micro-cracks.

Corrosion Resistance: Sulfur compounds, water vapor, and acidic components in exhaust gases accelerate corrosion of ordinary metals. The high nickel content in T304 stainless steel provides exceptional resistance to acid and alkali corrosion, significantly extending service life.

Technical Note: T304 stainless steel maintains its structural integrity up to 870°C (1600°F), far exceeding typical EGR system operating temperatures, ensuring long-term reliability even under extreme driving conditions.

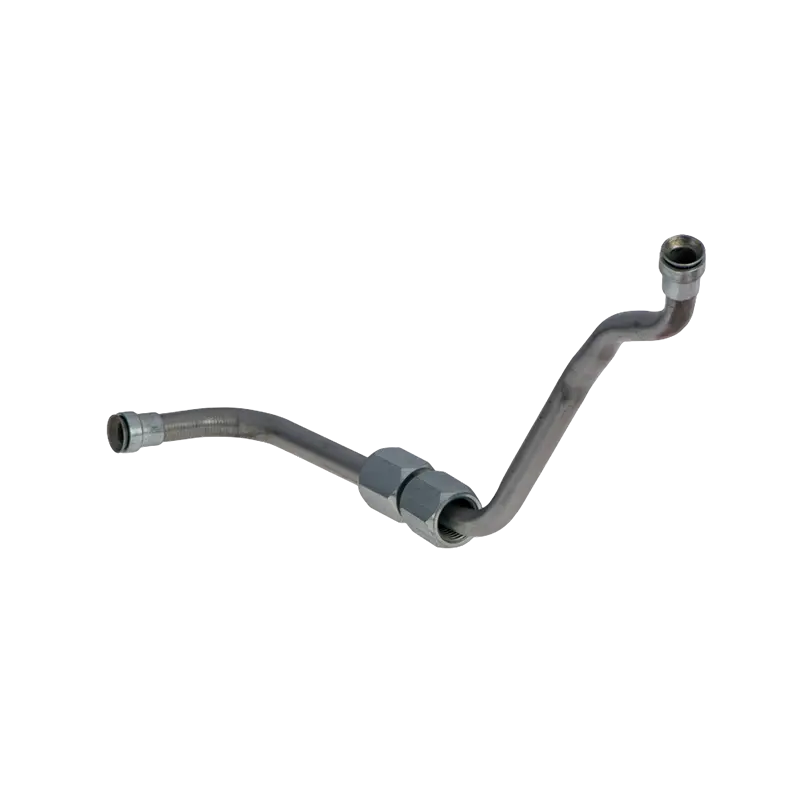

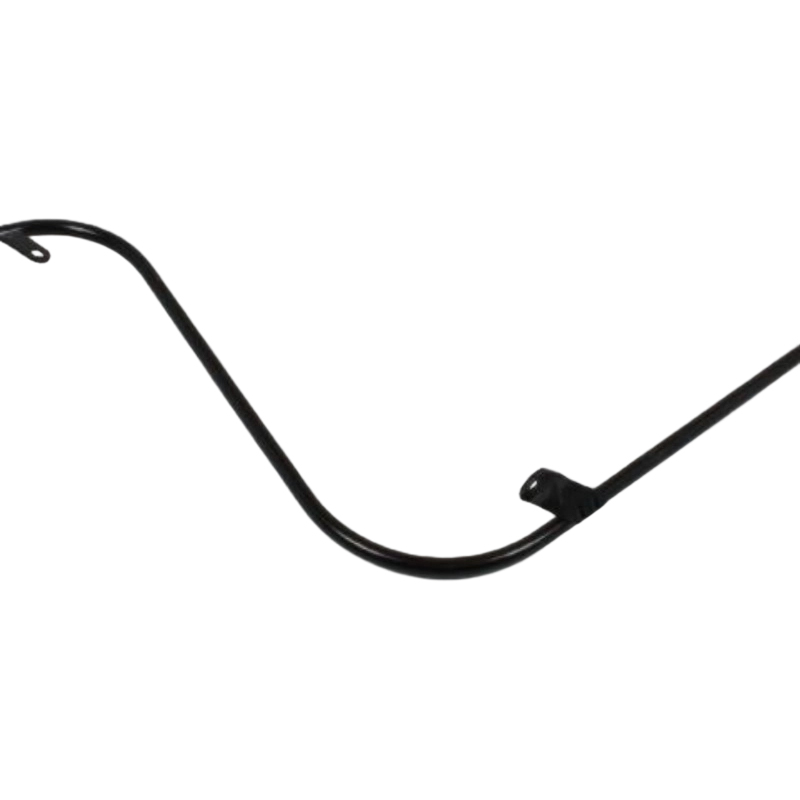

Precision Manufacturing Ensures Perfect Fitment

NINGBO JIATIAN's manufacturing process strictly adheres to original equipment specifications:

1. Mandrel Bending Technology: Unlike ordinary compression bending, mandrel bending ensures consistent cross-sectional area throughout the bend radius, avoiding wrinkles or deformation. This maintains smooth exhaust gas flow and preserves the EGR system's precise metering function.

2. Exact Angle Replication: Every bend angle perfectly matches the original part, ensuring proper installation in crowded engine bays without requiring forceful adjustment or pipe twisting.

3. Precision Fittings: Connection fittings use the same thread specifications and sealing surface design as original equipment, ensuring complete compatibility with EGR valves and exhaust/intake manifolds for true "direct replacement" without modifications.

Installation and Maintenance Guide: Maximizing EGR System Performance

Even the best replacement part can fail prematurely if installed incorrectly. Following proper installation procedures is crucial.

Professional Installation Recommendations

1. System Cleaning: Before installing a new EGR tube, consider cleaning the EGR valve and connection ports simultaneously. Carbon deposits accumulated in these areas may dislodge after new tube installation, potentially being drawn into the engine or affecting seal effectiveness.

2. Seal Replacement: Always use new gaskets or sealing rings. Aged seals cannot provide reliable sealing at high temperatures, potentially causing minor exhaust leaks that affect engine performance and emissions.

3. Torque Specifications: Tighten connection nuts strictly according to the vehicle manufacturer's specified torque values. Overtightening may damage threads or deform the pipe; undertightening will inevitably cause leaks. Typically, EGR tube connection torque values range between 15-30 N·m, but always refer to the service manual.

4. Pipe Alignment: Do not force alignment during installation. The OE E9SZ9D477B is designed to perfectly match the original position. If alignment proves difficult, check if other components (such as brackets or wiring harnesses) are obstructing proper installation.

Long-Term Maintenance Tips

After installing a new stainless steel EGR tube, proper maintenance can further extend its service life:

Frequently Asked Questions: Common EGR Tube Concerns

1. Is the OE E9SZ9D477B EGR Tube Compatible with My Vehicle?

OE E9SZ9D477B is a replacement for a specific original equipment part number. It is designed for vehicles using this original part number. Before ordering, verify against your vehicle's service manual, the part number on the original EGR tube, or consult a professional parts supplier. This product from NINGBO JIATIAN is a direct replacement, meaning it matches the original part exactly in dimensions, connection methods, and function.

2. Are Stainless Steel EGR Tubes Better Than Original Equipment Parts?

In many cases, yes. While original equipment parts meet all design specifications, manufacturers may not use the highest-grade materials in every vehicle due to cost considerations. Premium materials like T304 stainless steel are typically reserved for luxury vehicles or specific high-performance applications. Therefore, replacement parts made from quality stainless steel often offer better corrosion resistance and longer service life than standard original equipment parts.

3. Do I Need to Reset the Vehicle Computer After Installation?

On some newer vehicles, replacing EGR system components may require resetting the Engine Control Unit (ECU) or clearing related fault codes. Even though the EGR tube is a mechanical component, its failure may have caused the ECU to store adaptation values or fault codes. After installation, it's recommended to use a diagnostic tool to check and clear any historical EGR system-related fault codes, ensuring the ECU relearns optimal operating parameters.

4. What Cascade Problems Can EGR Tube Failure Cause?

A leaking or clogged EGR tube can lead to: incorrect intake temperature sensor readings, abnormal oxygen sensor signals, premature EGR valve failure due to incorrect flow, and even catalytic converter damage from unburned fuel. Timely replacement of a faulty EGR tube can prevent these more expensive repairs.

Conclusion: A Wise Preventive Maintenance Investment

While the EGR system may not be as prominent as the engine or transmission, it is crucial for modern vehicle emissions compliance, fuel economy, and overall performance. The OE E9SZ9D477B stainless steel EGR tube assembly represents a wise preventive maintenance choice—it addresses weak points in original designs with premium materials, offering longer service life and more reliable performance.

When facing EGR system-related symptoms, don't just consider the cheapest replacement option. Investing in a high-quality stainless steel EGR tube from professional manufacturers like NINGBO JIATIAN AUTOMOBILE PIPE CO., LTD. can prevent repeated repairs, protect other critical engine components, and ensure your vehicle continues to operate efficiently and cleanly for years to come.

Remember, in automotive repair, the principle of "doing it right the first time" is often the most economical choice. Selecting the correct part combined with professional installation will reward you with better performance and reliability from your vehicle.

English

English Espa?ol

Espa?ol